Getting a Good Score

1/2/2018 3:14:53 PM

By Jerry Hazelwood

As the idea of “Quality Deer Management” becomes more popular, some hunters are opting to pass smaller bucks and harvest only mature bucks with larger racks. Consequently, more sportsmen are becoming interested in the “score” of their buck’s antlers.

While there are several scoring systems, each with its own set of rules, the Boone and Crockett (B&C) system is widely accepted as the standard from which all others were developed. Therefore, this article will only deal with scoring white-tailed deer by the B&C method. Before the rack can be officially scored, it must have air-dried for at least 60 days, cannot have a broken skull plate, and cannot have artificially replaced points.

Any sportsman who has ever picked up an outdoors magazine knows that deer antlers develop into countless formations that often vary drastically from the typical 6-, 8-, and 10-point symmetrical racks. These are referred to as non-typical antler formations. The rules for scoring non-typical racks are lengthy and complicated and usually require the knowledge of a trained B&C measurer to score them correctly. Here, we will only discuss techniques for scoring typical racks.

Most trained scorers have experienced situations where hunters have brought previously scored antlers to them. Most of the time that initial score is very inaccurate and often higher than the official score—usually because of poor measuring techniques or calculation errors. Some of the most common measuring mistakes are discussed below:

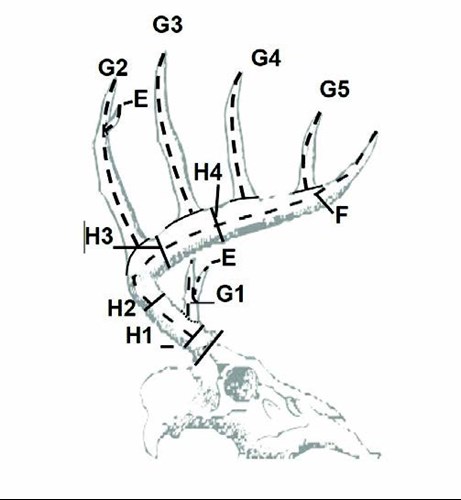

POINT DETERMINATION

Normal points arise from the top of the main beam and are usually symmetrically paired with similar-length points on the other antler. B&C denotes the main points on antlers as G1, G2, G3, etc., with G1 being the brow tines or eye-guards. The other points are numbered consecutively. Before starting to score the antlers, match the normal points from one side with those on the other side. If a point is unmatched at the end of a main beam, it is considered a normal point and a zero is entered for the measurement of the missing point on the opposite beam. If a point is unmatched between two normal points, it is considered abnormal and the length is recorded in the abnormal point section. The most common error relative to normal points is inappropriately matching points from one side to the other.

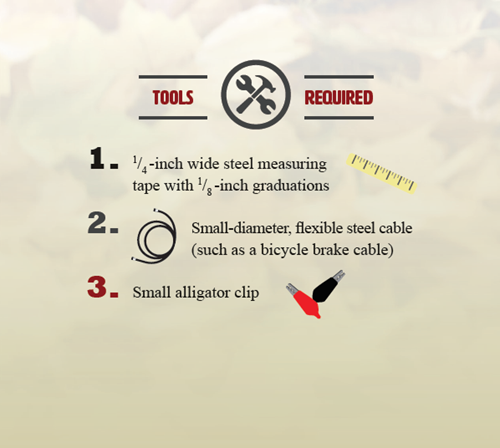

For scoring purposes, not all protrusions are measured as points. To qualify as a point, the projection must be at least an inch long with the total length exceeding the width of the point at one inch or more of length. To measure the length of a point, you must first establish the base of the point. This is accomplished by placing the steel cable along the top of the main beam or along the parent point across the base of the point being measured. The base is where the top of the cable crosses the bottom of the point. The point length is then measured from the tip to this base along the center line of the point using the steel tape.

Any point that does not arise from the top of the main beam is considered an abnormal point. Abnormal points include drop tines and points arising off other points or the burr line. The two most common errors in determining point length is measuring the length from the center or bottom of the main beam and measuring protrusions that do not meet the criteria to be a point.

BEAM LENGTH

The length of the main beams is measured using the flexible cable and alligator clip. Start by finding the lowest edge on the burr line in the center of the beam and use this as the starting point for the length of that beam. Pull the cable up along the outside of the antler, following the center of the beam out to the tip. Place the alligator clip at the tip of the antler and measure the cable length with the steel tape. The most common error incurred is using a steel tape that does not flex when bending around the curve of the beam.

CIRCUMFERENCES

Four circumference measurements (denoted as H1, H2, H3, and H4) must be recorded for each beam. The H1 circumference is the smallest measurement between the burr and the origin of the first point (G1). If there is no G1, take the circumference at the smallest point between the burr and G2 and use this measurement as H1 and H2. All other circumference measurements are taken at the smallest point between the succeeding G points.

If there is no G4, H4 is taken halfway between the center of the base of G3 and the tip of the main beam. In the case of a normal 6 point where there is no G3 or G4, find the halfway point from G2 and the tip of the main beam and take the circumference there and use this as H3 and H4 measurements. The most common errors relating to circumferences are using the largest circumference measurements rather than the smallest and not recording an H4 for beams without a G4.

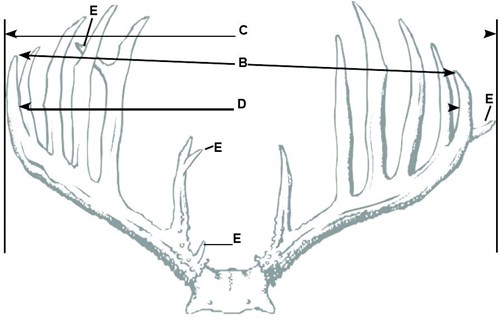

INSIDE SPREAD

The inside spread of main beams is measured at a right angle to the center line of the skull at the widest point between the main beams using the steel tape. Inexperienced measurers will often angle the measurement to get the greatest inside spread regardless of the angle of the tape relative to the skull.

The inside spread credit can equal but not exceed the longest main beam length. For example, if the inside spread is 20 inches, and the longest of the two main beams is 18 inches, then 18 inches is used as the inside spread credit. The most common error relating to measuring inside spread is not being perpendicular to the skull at the widest point.

SCORE CALCULATION

The underlying basis for scoring antlers is symmetry between the left and right sides. Therefore, in scoring a typical rack, differences between same measurements from each side are deducted from the gross, or total, score. Abnormal points are also deductions. To calculate the score, first find the differences between each corresponding measurement, such as G1 on the left minus G1 on the right, for all G-point measurements. Do the same for each H measurement. Add together all of the deductions to get the total deduction number.

To get the gross score, add the inside spread, beam lengths, all the G-point lengths, and all H-circumference measurements. Finally, subtract the total deduction number from the gross score to get the final, or net, score. The most common errors in score calculation are addition and subtraction errors.

The minimum net score required of a typical whitetail B&C entry is 170 for the all-time records and 160 for the awards book. For entry into Mississippi’s Magnolia Records Program, the minimum required score is 125 net for typical racks.

For additional instructions on scoring, visit www.boone-crockett.org.

Jerry Hazelwood is a retired Wildlife Biologist for the MDWFP. To subscribe, call toll-free 1-888-874-5785.